Given that 20 companies produce more than half of all single-use plastic in the world, a vital shift is needed in how businesses and industries produce, consume and dispose of plastic. There are several things businesses and industries can do to reduce plastic production and use.

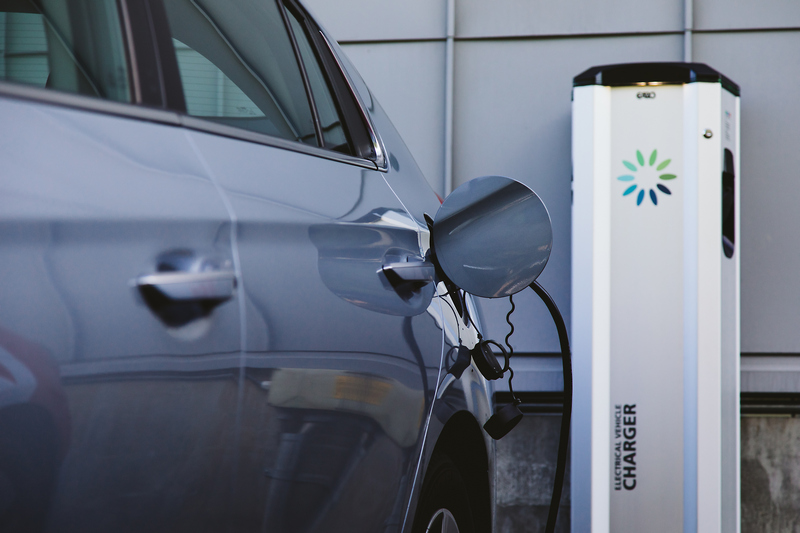

Electrify your fleet by making the transition to electric, your employees will be driving enviromentally friendly vehicles as EV’s do not emit pollutants.

Install Electric Vehicle Charging Infrastructure. With the rapidly growing interest in EV’s, it is imperative for all workplaces to offer the EV charging facility to their employees and by doing so, you will greatly reduce carbon footprint at your workplace.

Design out waste by eliminating and substituting unnecessary and hazardous plastic production and packaging, especially single-use plastic.

Reduce the amount of plastic waste produced throughout operations, particularly in manufacturing and packaging.

Improve plastic design and production to ensure products are reusable, minimally resource-intensive and can be recycled effectively.

Cut costs through more efficient use of plastic, develop new revenue streams through ‘closed-loop’ business models that recover plastic as a useful resource and win customers by demonstrating more sustainable products.

Leverage emerging technologies to develop profitable solutions to plastic pollution that support environmental, social and governance goals.

Disclose more information about how much plastic is used in products, including plastics produced annually, as well as the chemicals used in plastic.

Switch from plastic to mulch films in farming and embrace nature-based solutions, such as cover crops, which protect soil from erosion, weeds and pests.

Join hundreds of other businesses worldwide in committing to actions across the plastics life cycle through the New Plastics Economy Global Commitment to eliminate, innovate and circulate plastics.

Join the Global Tourism Plastics Initiative, which aims to eliminate unnecessary single-use plastic and transition to reusable products.

Transitioning to circular approaches and plastic alternatives is critical. This involves a life-cycle approach – one where the impact of all the activities and outcomes associated with the production and consumption of plastic is considered. This includes reassessing raw material extraction and processing, and innovating manufacturing processes, product design, packaging, distribution and end-of-life management, such as segregation, collection, sorting, recycling and disposal. Addressing plastic pollution requires a systemic change, with actions across the life cycle that address its root causes rather than its symptoms. This is a big challenge, but one that we must take on.